Precision Turning for Aerospace Defense Space Components

Precision turning for aerospace defense space components requires an experienced company with a proven record of quality. At Intrex Aerospace, we have the experienced staff and strict quality controls needed to produce a variety of precision aerospace components. Our facility is both ISO 9001:2000 and AS9100 Rev. B certified. We utilize a variety of quality control measures including SPCs, CMMs and climate-controlled testing rooms. This attention to detail produces PPMs well below industry standards.

Precision turning for aerospace defense space components requires an experienced company with a proven record of quality. At Intrex Aerospace, we have the experienced staff and strict quality controls needed to produce a variety of precision aerospace components. Our facility is both ISO 9001:2000 and AS9100 Rev. B certified. We utilize a variety of quality control measures including SPCs, CMMs and climate-controlled testing rooms. This attention to detail produces PPMs well below industry standards.

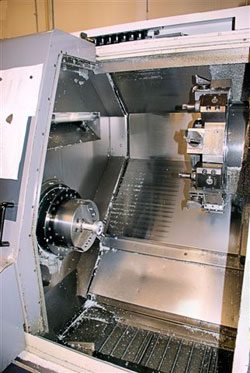

Many of our machinists have more than 20 years of experience in precision CNC lathe turning. They are capable of producing turned parts in a variety of aerospace materials including titanium, stainless steel, hastelloy and more. Intrex has 5-axis precision turning capabilities and lathes to produce turned parts up to 10” x 40”.We specialize in producing thin-walled parts. As part of our continuing investment in our capabilities, we’ve recently added two high-speed Mori Seiki Model NLZ-2500 lathes in a dedicated flange cell.

In addition to our precision turning, Intrex offers program management services for customers with LTAs. As you aerospace manufacturer, we can simplify your supply chain by managing every step from prototyping through delivery. The efficiencies gained through this management save you both time and money on your parts program. We also utilize an Epicor ERP/MRP system to manage kanban and production forecasting through EDIs.

For more information on our precision turning services, contact Intrex Aerospace today.