Machining Thin-Wall Parts

One of the major considerations in aircraft design is total weight reduction of the aircraft. This lower weight criteria translates not only to aerostructure, but also down into the individual components. The components not only have to weigh less, but they also need to maintain or exceed in strength. It takes experience and knowledge to supply these types of parts to the aerospace market. One of the primary skill-sets of Intrex Aerospace produces machining thin wall parts.We apply our years of experience, coupled with our up-to-date CNC machines, to produce high quality thin-walled parts. The machining of thin-walled parts presents challenges beyond standard machining practices. These challenges apply to both turning and milling.

One of the major considerations in aircraft design is total weight reduction of the aircraft. This lower weight criteria translates not only to aerostructure, but also down into the individual components. The components not only have to weigh less, but they also need to maintain or exceed in strength. It takes experience and knowledge to supply these types of parts to the aerospace market. One of the primary skill-sets of Intrex Aerospace produces machining thin wall parts.We apply our years of experience, coupled with our up-to-date CNC machines, to produce high quality thin-walled parts. The machining of thin-walled parts presents challenges beyond standard machining practices. These challenges apply to both turning and milling.

There are four fundamental concerns of machining thin-wall parts. These include:

Rigidity

Successful machining of thin-wall space components requires experience, understanding, and application of correct tooling to compensate for poor workpiece rigidity. Standard machining practice is undermined by the thin-wall workpiece definition. Thin-wall workpieces resist applying “normal” tool pressures, thus many standard machining practices are not effective.

Deformation

Successful machining of thin-wall parts requires having an understanding of why parts deform during the machining process and applying this knowledge and experience to a solution. Thin-wall design parts have a tendency to want to deform during the machining process. Inherent to thin-wall parts is a weakness caused by thin walls. Machining success is determined by understanding the forces that lead to deformation.

Work Holding

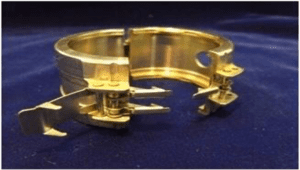

Improper work holding can easily distort thin-wall parts. Consideration must be given to part distortion during the machining process. Many parts require special work holding, special chuck jaws, and special chucks. Intrex has experience with implementing these types of solutions.

Correct Tooling

Proper knowledge and experience of tool geometries and the application’s proper feeds and speed is essential to successfully machining thin-walled parts. Machining thin walls present unique challenges to avoid part distortion. Intrex Aerospace has the tooling knowledge and experience to solve these machining challenges.

The aerospace markets have many applications for thin-wall parts. Intrex Aerospace has a long and successful history of producing thin wall parts. We produce these machined components in many different sizes and shapes. Our capital investment in CNC machines and support equipment is a testimony to our commitment to our customers and the aerospace thin-wall market.

Many of our late-model purchases of CNC machines have multi-spindles and multi-axis simultaneous machining. There are inherent advantages in CNC multi spindle, multi-axis machines. They can greatly reduce work setups. Our 5-axis machines can machine nearly every visible surface, excluding the bottom or clamping area. This ability can significantly reduce the need for additional chucking/clamping and in many cases eliminates the need for special fixtures. By reducing the number of chucking/clamping, you reduce the possibilities for part distortion.

In addition to our years of experience providing thin-walled machined components for the aerospace market, Intrex provides the systems service and support to meet the most demanding supply chain requirements. Our Epicor ERP/MRP system is state-of-the-art.

We would welcome an opportunity to discuss your thin-wall machining requirements. For more information, please click here.