Tight Tolerances for CNC Machined Parts

Achieving tight tolerances for CNC machined parts is very difficult without state-of-the-art CNC machines. Aerospace components vary in size, shape, material, and tolerance. CNC machines are ideal for producing machined components, from the simple to the complex. Properly maintained machines can consistently produce accurate parts.

Achieving tight tolerances for CNC machined parts is very difficult without state-of-the-art CNC machines. Aerospace components vary in size, shape, material, and tolerance. CNC machines are ideal for producing machined components, from the simple to the complex. Properly maintained machines can consistently produce accurate parts.

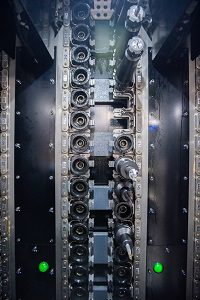

At Intrex Aerospace, we have over 40 pieces of CNC equipment on our shop floor. Our machines vary from CNC lathes (2-3-4 axis), vertical CNC machine centers (3-4 axis), horizontal machine centers (3-4 axis), and twin-spindle CNC mill/turn (up to 7 axis, 5 axis simultaneous machining). Because of the wide range of our CNC capability, we can produce complex shapes and sizes in multiple materials.

Our latest models of multi-axis CNC machines with two spindles are well suited for producing precision parts in low-to-medium lot sizes. Our CNC mill/turns with ATCs (automatic tool changers) offer a good solution for short run parts (where most of the demand in aerospace is). The design of our CNC mill/turns helps reduce setups, minimizes operator intervention, and lessens dependence on special fixturing—all of which improves part quality and efficiencies, shortens lead times, and helps take cost out of the part.

Our latest models of multi-axis CNC machines with two spindles are well suited for producing precision parts in low-to-medium lot sizes. Our CNC mill/turns with ATCs (automatic tool changers) offer a good solution for short run parts (where most of the demand in aerospace is). The design of our CNC mill/turns helps reduce setups, minimizes operator intervention, and lessens dependence on special fixturing—all of which improves part quality and efficiencies, shortens lead times, and helps take cost out of the part.

In addition to having 40+ CNC machines, we have seven CNC CMM (Coordinate Measuring Machines) on our shop floor. These machines are strategically located in cells for ease of operator and quality access. All our floor CMMs are linked to our Epicor ERP/MRP system. All measurements are recorded and reported through this system. This information can be monitored and tracked. Access to any supporting documentation (shipping documents, e.g.) can be easily provided.

In addition to having 40+ CNC machines, we have seven CNC CMM (Coordinate Measuring Machines) on our shop floor. These machines are strategically located in cells for ease of operator and quality access. All our floor CMMs are linked to our Epicor ERP/MRP system. All measurements are recorded and reported through this system. This information can be monitored and tracked. Access to any supporting documentation (shipping documents, e.g.) can be easily provided.

To learn more about our program management services and demand management that our company has to offer, contact Intrex Aerospace today.