CNC Machining Requires Quality Control

When choosing a contractor to handle precision CNC machining requires quality control capabilities. Quality control focuses on a business’s ability to identify flaws and react quickly to address them, while quality assurance focuses on preventing flaws from occurring in the first place. Only by addressing both can a firm consistently deliver high-quality components, particularly in industries like aerospace and defense where part tolerances are very strict.

When choosing a contractor to handle precision CNC machining requires quality control capabilities. Quality control focuses on a business’s ability to identify flaws and react quickly to address them, while quality assurance focuses on preventing flaws from occurring in the first place. Only by addressing both can a firm consistently deliver high-quality components, particularly in industries like aerospace and defense where part tolerances are very strict.

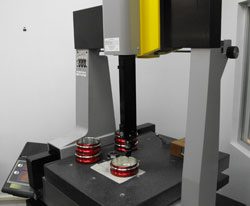

Being able to maintain quality control requires manufacturers to have the tools in place to both identify and properly measure variations in production. Since precision CNC machining requires strict tolerances, businesses need to be sure that their quality control equipment is sensitive enough to properly measure components, using a coordinate-measuring machine (CMM). Businesses may also utilize statistical process controls (SPCs) to identify the causes of variations in production. These variations, once identified, can then be monitored and addressed, leading to a greater percentage of parts conforming to tolerances.

While quality control is focused on maintaining and improving existing processes, quality assurance focuses on setting up processes in order to avoid mistakes. This often involves repeated testing of source materials as well as components and assemblies while prototyping production. If a manufacturer has well defined procedures in place for FAIs and PPAP/SPAP, then it is a good indication that they are well versed in quality assurance procedures.

Businesses looking for precision CNC machining services with reliable quality control and quality assurance can turn to Intrex Aerospace. Our company utilizes a variety of tools, including an IQS software package for our Epicor ERP system, and CMMs in a climate controlled environment, to consistently maintain the quality of our products. We operate with a PPM well below industry average, and our ISO 9001 and AS9100C certifications attest to our ability to meet the highest quality standards.

To learn more about our precision CNC machining services, contact us today.