Advantages of 5-Axis Machining

Often modern machining requires multiple simultaneous axis movement. In the past, such parts could be produced, but it required multiple setups and multiple machines, usually a combination of turning and milling machines. Thanks to advances in machine design, machine controls, servo and tooling technology, we can now accomplish multi-axis simultaneous machining on a single platform. There are many advantages to 5-axis machining. You can now produce complex shapes in a single chucking.Because of the complex shapes and tighter tolerance requirements of the aerospace/defense/space markets, the current 5-axis CNC machines are ideally suited for this type of manufacturing.

Often modern machining requires multiple simultaneous axis movement. In the past, such parts could be produced, but it required multiple setups and multiple machines, usually a combination of turning and milling machines. Thanks to advances in machine design, machine controls, servo and tooling technology, we can now accomplish multi-axis simultaneous machining on a single platform. There are many advantages to 5-axis machining. You can now produce complex shapes in a single chucking.Because of the complex shapes and tighter tolerance requirements of the aerospace/defense/space markets, the current 5-axis CNC machines are ideally suited for this type of manufacturing.

5-Axis Machining—Defined

Traditional CNC machines move in two linear axes (X and Z) for lathes and three linear axes (X, Y, and Z) for machining center. The term “5-axis” refers to the number of axes in which the cutting tool or the workpiece moves. In 5-axis machining, the cutting tool moves across the X, Y, and Z linear axes, and the workpiece rotates on the A and B (or C) axes.

The ability to precisely move the workpiece without re-chucking has distinct advantages over conventional 3-axis machining.

The benefits of 5-axis CNC machining include:

Ability to Produce Complex Shapes

The major (and most well-known) advantage of 5-axis machining is the ability to machine complex shapes. The ability to a machine in a continuous axis move creates machining angles and arcs for the cutting tool and for chip relief that were only previously possible with a multitude of special fixtures or additional setups.

Improved Tool Life

More complete control of all simultaneous axis movement gives better control of chip load and maintains optimum cutting tool position, leading to better tool life, part tolerance, and finish.

Reduced Setup

Five-axis machines can machine nearly every visible surface, excluding the bottom or clamping area. This ability significantly reduces the need for multiple setups or special fixtures. In some instances, it reduces the number of setups to one.

Better Accuracies

Every time you have to re-chuck your workpiece, you introduce a possibility for error. By greatly reducing setups, you reduce possibility for error and eliminate the cumulative tolerance stack. Five-axis machining increases uptime, decreases human error, and eliminates the need for special fixtures.

Improved Surface Finishes

Using the rotating fourth and fifth axes, the part can be orientated to bring it closer to the cutting tool. If the part can get closer to the cutting tool, then the cutting tool can be shorter. A shorter cutting tool is less susceptible to vibration at higher cutting speeds, which directly impacts surface finish.

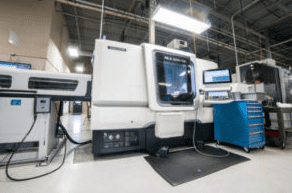

Investing in Your Success

As technology improves, so do the markets’ expectations for higher quality products at competitive pricing. To meet this challenge, Intrex has made significant investments in multiple-axis equipment as well as systems software to oversee and control our entire manufacturing process.

We would welcome an opportunity to speak to you about addressing your supply chain needs.