CNC Machining Services – Offering A Single Source Solution

Mar 07, 2022What does it take to provide a complete CNC machining service? It starts with years of experience successfully producing precision machined parts for aerospace, space, and defense industries. Taking our investments and experience, translating them into building an organization that will meet the market needs as we move forward in providing a single source solution.

There are foundational steps that Intrex has implemented that allow us provide CNC Machining Services – Offering A Single Source Solution . We confidently move toward the future, as a world-class supplier of precision machined CNC components. Every step in this process is integrated with adjoining steps. It requires knowledge of the marketplace, willingness to make investments in buildings, equipment, and educating our workforce. The result of this strategy is to provide a seamless, single-source machining solution.

Investments Made

Building

To meet our increased demands for competitively priced component parts for aerospace, space, and defense, we moved from a 25,000 sq. facility into our current 75,000 sq. ft. building in Thornton, CO. Our Thornton building is a clean, modern, state-of-the-art manufacturing facility. It is part of our commitment to providing a single source solution.

Equipment/Software

Our capital purchases of equipment and software are ongoing. Each addition and upgrade is added with the understanding that these investments improve operational efficiencies, drive down cost, and better meet our customer needs.

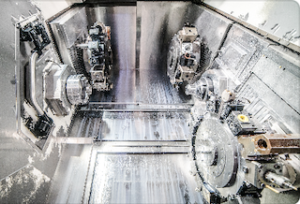

Our CNC multi-axis equipment (turn/mills, horizontal machine centers, vertical machine centers, Zeiss CMMs), offers a single-source machining solution. Our many years of machining experience and expertise, coupled with our Epicor ERP/MRP system, can solve your most demanding supply source needs.

CNC Machines

- 1 – Okuma LT-300MY twin spindle, twin turret, turn/mill, 7-axis w/ robot

- 1 – DMG/Mori NTX 2500 Series 5-axis turn/mill w/60 ATC

- 3 – DMG/Mori NLX2500SY/700 turn/mill

- 1 – DMG/MoriNLX2000 SY/ turn/mill with Y-axis

- 1- DMG/Mori CMX 1100

CMMs

- 5- Zeiss DURA VERTICAL Model 5100

ERP/MRP

Benefits of Our Epicor ERP/MRP

Managing and aligning your production with your suppliers scheduling needs requires a powerful ERP/MRP system. We have made significant investments in our Epicor system. It is powerful, flexible and robust. It allows us to align our production with our customer’s demands. Our system can be integrated with our customers’ forecast portal, for real-time monitoring and management. This allows us to adjust our production to match our customers’ needs. The improved efficiencies gained through our Epicor ERP/MRP system allow us to be more responsive to our customer’s needs.

Quality Assurance Integrated with Epicor ERP/MRP

Having a quality assurance program is one of the keys to successful machining of aerospace parts. Aerospace/space/ defense components require careful and constant monitoring of the quality process. Our quality assurance program at Intrex Aerospace, provides real-time detailed information of production part status, with critical quality measurements, and supporting documentation. Our quality assurance is integrated with our Epicor ERP/MRP system. All phases of the manufacturing process are measured and recorded.

Our investment in a quality management software package, allows us to track a range of quality control metrics. We can provide CPk and SPCs where requested. We can also use it to generate reports that allow our customers to see the results. This level of integration allows us to maintain PPMs less than 50, and OTDs of 98-100.

Staffing & Training

We are committed to providing the highest level of training throughout our shop. We have ongoing in-house training for all our employees. In addition, we also have:

- In-house internal auditors, they audit monthly for AS 9100 compliance and improvement.

- We also train our staff in Six Sigma principles. Lean Six Sigma methods are rooted in process-improvement systems.

It takes investments in systems, equipment, and training to make and maintain the aerospace performance metrics work. This high level of integration and performance allows Intrex to providing a single source solution. If you would like more information about our single-source machining solutions please click here and we will contact you.