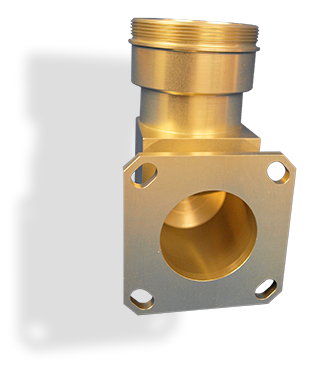

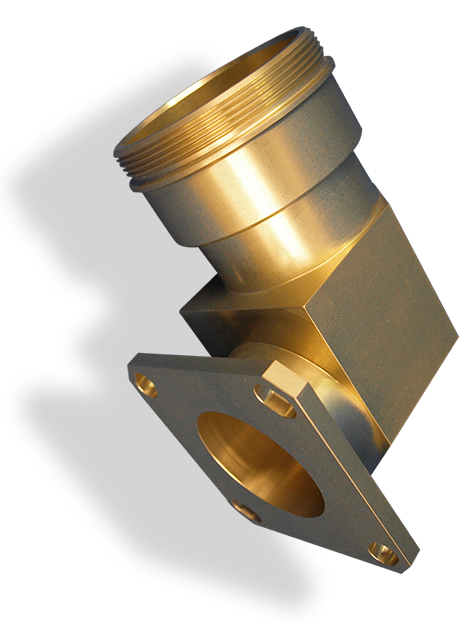

Our focus is on critical–to–quality machined components for aerospace, defense, and space.

If you’re in the market for comprehensive supply chain interactions for your defense, aerospace, or space projects, let the Intrex Aerospace team put its expertise to work. Our 30+ years of experience as a precision machining company allows us to stay on the cutting edge of machining technology while delivering the highest quality components, on-time.

When you work with Intrex Aerospace, you benefit from access to precision CNC machined components made specifically to your requirements. Our multi-axis, CNC equipment (turn/mill lathes, horizontal and vertical machine centers and modern support equipment ensures our ability to see your project through from purchasing raw stock to providing a finished product.

Focused Quality Management

Our Enterprise Quality Management System is integrated into our entire production process. Every part we produce is monitored through our quality system. Our staff is trained and committed to delivering parts that meet or exceed our customers’ specifications. We have some of the lowest PPM’s in our industry.

At Intrex our quality assurance process is totally integrated with our manufacturing process. This ensures that all relevant data needed to manufacture products are all operating under the same system. Once the product has been produced and gone through all the steps in our quality system that meet all your quality requirements, the packaging and documentation are pulled together and included in our shipping documents.

Intrex Aerospace is also ISO 9001 and AS9100 certified. Part of this certification process is training our staff. All our employees receive regular training in AS and ISO standards and are very knowledgeable in the requirements and procedures needed to maintain these certifications.

Program Management

We rely on Epicor ERP/MRP system software, to oversee our manufacturing process. It allows us to schedule and track parts as they flow through our shop floor. It can address the following:

- Engineering support

- Raw material sourcing

- Part machining

- Special process management

- Documentation

- Shipment

Why Choose Intrex?

When you assess your needs for your next defense, space, or aerospace project, your supply chain partner must be able to match your needs. The aerospace machining companies you choose to work with must provide you with the best possible solution for your next project.

Pair the aerospace precision machining company’s experience with its access to cutting-edge technology, and the Intrex team stands out as a high-quality provider of complex manufacturing solutions.

State of the Art Production Technology

We have access to some of the cutting-edge technology needed to be a successful supply chain partner and are willing to invest in time and equipment, to make a partnership better.

The means we have to put at your disposal include:

- Epicor ERP and MRP system software

- CNC machining lathes

- 5-axis machining

- Complex turn-milling

- Thin wall machining

We have the equipment and experience to provide most solutions for your machining requirements. We would welcome an opportunity to meet with you, to discuss your needs.

Excellent Customer Service

We provide a high level of response to not only your quoting requirements but also to any post sale questions. Most of our business is “program” business, involving LTA’s (Long Term Agreements). These agreements involve constant communications from both parties, making changes to schedules, etc. And we are very experienced in and good at it.

ITAR Compliance

To successfully manufacture machined parts for our defense customers, Intrex is very experienced with International Traffic Arms Regulations. A larger percentage of work flowing through our shop at a given time is defense-related. If you have DOD-type work that needs sourcing, please give us consideration.

Learn More